SolarSpring Membrane Distillation

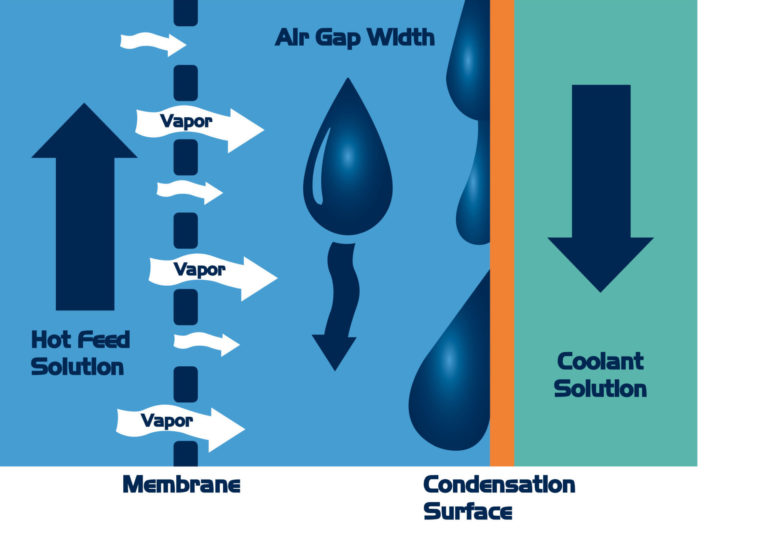

Depending on the application, one of five different membrane distillation channel variants are implemented:

- Permeate Gap MD (PGMD)

- Direct Contact MD (DCMD)

- Air Gap MD (AGMD)

- Vacuum MD (VMD)

- Vacuum Air Gap MD (VAGMD)

Advantages of MD-technology:

- High chemical resistance towards corrosive or acidic process liquids

- Maintenance friendly systems with simple component replacement

- System integration into existing processes

- Competitive economics compared to state of the art solutions

- Cost reduction of your total process costs

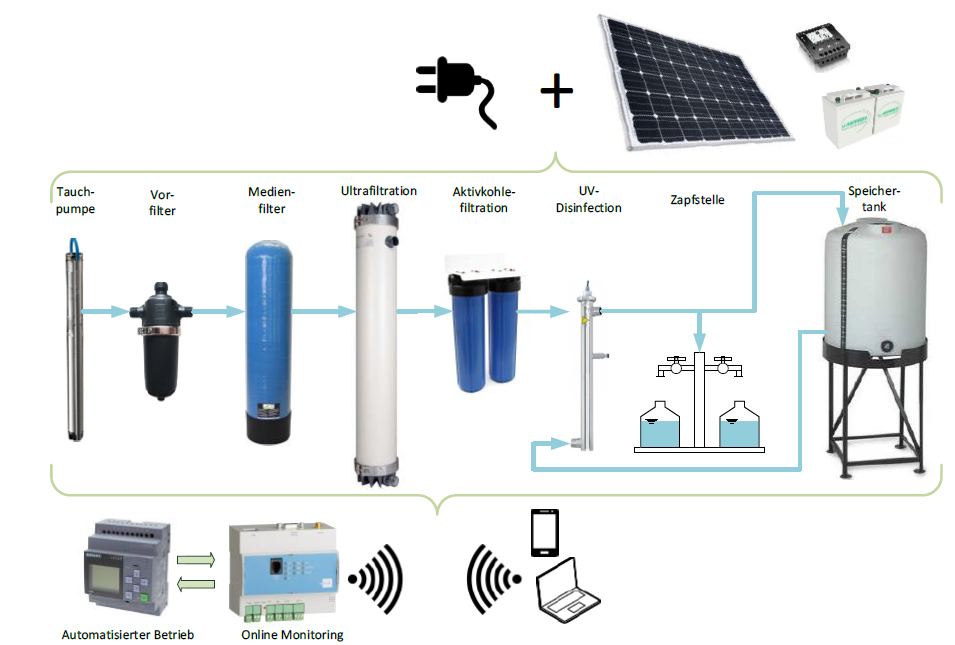

SolarSpring drinking water treatment

Our drinking water filtration systems are a smart combination of 5 stages; an Ultrafiltration module, a sandfilter, a disk filter, an activated carbon stage and an Ultraviolet-Disinfection unit. Interaction between the stages is synchronized and fully automatic – self-sufficient cleaning cycles enable a constant and smooth operation. A cubic meter of drinking water only takes 0,3 kWh of electric energy to produce at an operating pressure at 2,5 bar.

Night time operation is sustained by an AGM-Batterie which is charged during the day time through the solar panel and charge controller- all included in the package. For remote monitoring, a 3G module can be added to the Siemens Logo PLC so that you always have an eye on all the important parameters.

Operating scheme SolarSpring Multi Barrier System

SolarSpring Ultrafiltration

Ultrafiltration is a filtration technology that utilizes a semipermeable membrane as physical barrier, through which the feed water is pressed under pressure. Typical pore sizes of ultrafiltration systems are between 0,01 and 0,1 µm. Suspended solids and larger dissolved substances are held back whereas water and dissolved substances that are smaller than the pore size can pass through the membrane.

Ultrafiltration technology reliably retains 99,999% of microorganisms, bacteria and viruses. As it is a very efficient low- pressure process, the energy consumption is also low.

Ultrafiltration is increasingly implemented in advanced drinking water treatment processes around the globe. In comparison to standard drinking water treatment methods, ultrafiltration has many advantages:

- Consistent quality of the produced drinking water

- Uncomplicated automation

- Low surface requirements

- Low operational costs

Clean water with clean electricity

Billions of people still have no access to clean drinking water or lack adequate sanitation. Residents of rural areas are particularly affected.

If drinkable water is needed far away from any infrastructure, SolarSpring’s water treatment systems can help. The system can produce up to 200,000 liters of clean drinking water per day even from heavily polluted surface and ground water.

Clean drinking water without chemicals

Several treatment stages make it possible that the drinking water is not only clean but also safe. Our water treatment systems filters 99.999 % of all bacteria and viruses from the existing water – and this completely without the use of chemicals. This is made possible by a combination of ultrafiltration, activated carbon filtration and UV disinfection.

High-quality components, automatic operation with PLC and online monitoring characterize this compact water treatment system.

Low maintenance and solar powered

The maintenance of the system can be carried out on site by any plumber. A notification of the need for maintenance can be sent by email or SMS if required. The system requires a mains connection for operation. Alternatively, the water treatment systems can be equipped with solar modules, PWM charge controller and an AGM battery, so that it can produce clean and safe drinking water almost anywhere in the world. To protect the water treatment systems from external influences, it is installed and supplied in a robust powder-coated steel cabinet.