SolarSpring provides treatment solutions for wastewater volume reduction as well as water and ressource recovery.

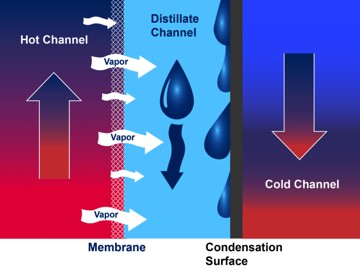

A key technology within the portfolio of processes is the rEvap membrane evaporator technology, a self- developed system based on membrane distillation. Together with state of the art water treatment techolgies rEvap greatly enhances the range of treatment possibilities, especially for challenging industrial wastewater applications which previsously could not be processed sufficiently.

With rEvap, ingredients from industrial effluents can be concentrated to a reusable level and can be fed back into the industrial process together with the clean water obtained in the process.Industry Segments:

Metal industry

- Recycling of acids

- Recovery of gold and other rare plating metals

- Nickel recovery

- Pickling bath recycling

Brine Treatment

- Zero or minimal liquid discharge

- Recovery of process salts

- Volume reduction of high salinity wastewater

Ammonia removal

- Ammonia removal from municipal wastewater

- Simultaneous conversion of ammonia to fertilizer

- Ammonia removal from industrial/pharmaceutical effluents and production processes

Oil and Gas

- Volume reduction of wastewater

- Reuse of purified water

A closer look – rEvap membrane distillation technology:

Products:

rEvap

The rEvap technology is the perfect solution for small and medium-sized companies that want to close material cycles and minimize disposal costs. The plants are equipped with a plate module. We would be pleased to carry out appropriate preliminary tests for you.

Technical details:

- For process water / waste water up to 1 m³/h

- Fully automatic

- Controlled via Siemens SPS

- Adaptable according to customer requirements

- All channel geometries possible

- Suitable for endurance run

References:

- ReWaCEM, Resource recovery from industrial waste water by cutting edge membrane technologies, 2020

- BrineMine: Extraction of valuable substances and drinking water from geothermal sources in Chile

- Process for the recovery of ammonium from wastewater by membrane distillation

- Project “RE-Salt” – Recycling of industrial process brines

- HighCon, The development of innovative, multi-stage and selective processes for the reuse of industrial wastewater, 2019.

- Printed Circuit Board / AT&S – Fehring, Austria

- Electroniquel, Spanien, 2019, Metallbeschichtung: Rückgewinnung von Schwefelsäure und Kupfer aus der Galvanisierung

- Tecnozinco Italien, 2019, rEvap, Feuerverzinkung: Rückgewinnung von HCl, Eisen und Flussmittel aus dem Beizen

- Deutsche Edelstahlwerke

Rückgewinnung von gemischten Flusssäure- und Salpetersäure-Beizlösungen aus der Walzdrahtproduktion von Edelstahl - King Abdullah University of Science and Technology

MDPilot - CIRCE – Research Centre for Energy Resources

MDPilot - University of Nevada

Reno, USA - Gran Canary, Spain

- MD Teneriffa

- GE

Munich, Germany

All references >